Hitzebeständig 3D Epoxy Boden für Küche

- MTBJZJ

- Shenzhen, China

- 1-5 Tage

- 10000 KGS pro Woche

Hitzebeständigkeit 3D Epoxy Boden für Küche

Visueller Effekt - Der bedeutendste Vorteil von Epoxy - 3D Stock ist die beeindruckende visuelle Wirkung.

Hohe Festigkeit - Epoxy ist praktisch undurchlässig, und sehr beständig gegen Säuren, Chlor und andere Materialien wie Bleichmittel und tägliche Reinigungsmittel.

Einfache Wartung - Epoxy 3D Boden hat keine Nähte, Fugen, Risse, Poren und Lücken machen den 3D - Bodenbelag auf jede Art von Schmutz, Staub, Wasser und Chemikalien absolut immun ist.

Sicher und Hygiene freundlich - Epoxy 3D Boden nicht accumulate Staub und schafft kein ein günstiges Umfeld für eine Vielzahl von Krankheitserregern / Bakterien.

Brandschutz - Epoxy / Polymere nicht brennen, ist es einer der Gründe dafür , dass die Beschichtung verwendet in der Herstellung, Lagerhallen, Krankenhäusern, Kindertagesstätten und andere Orte , an denen eine erhöhte Kontrolle des Brandschutzes erforderlich sind.

Heat Resistance 3D Epoxy Floor For Kitchen

This kit includes

- 21KGS Epoxy Resin and Hardener - No Tools

- 1KG Liquid Color Pigment

Can cover 200 square feet at least

Details for Kit

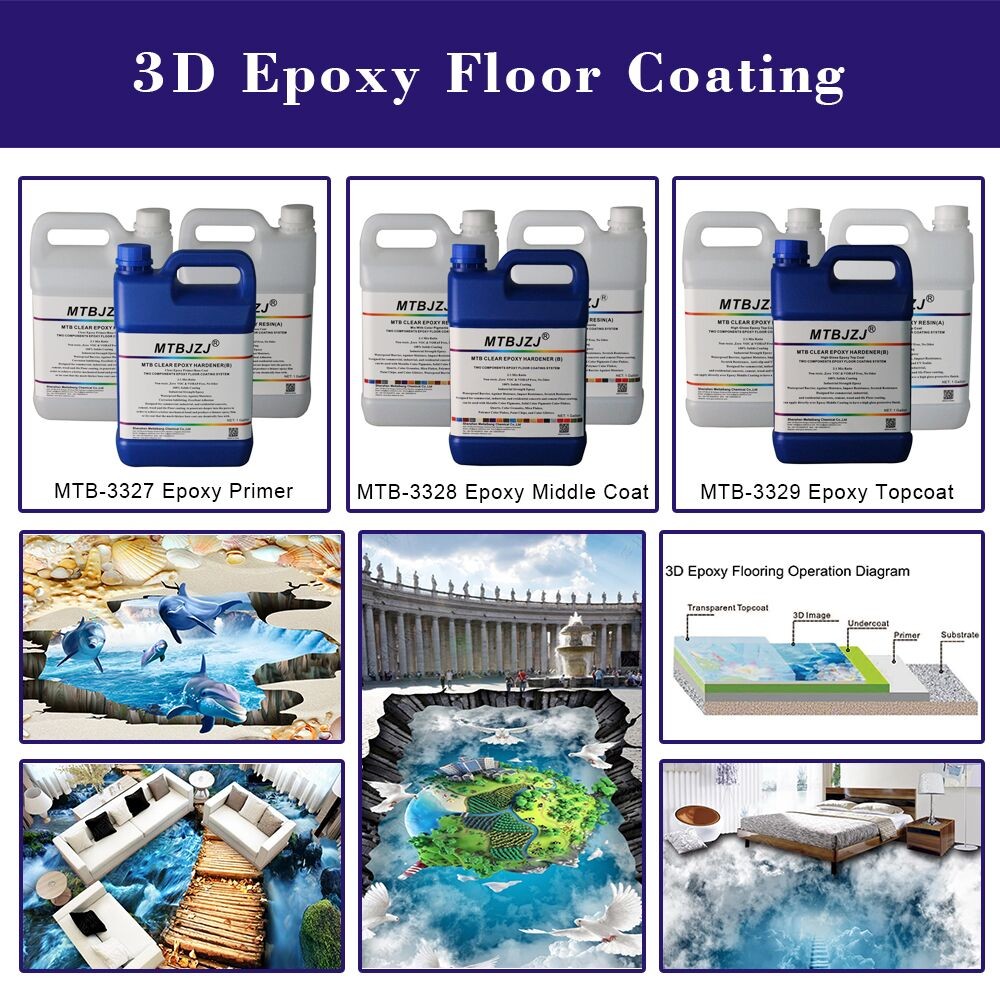

1.MTB-3327 Epoxy Primer Coat , 3kgs Kit

- Clear, 2:1, 2kgs of Epoxy Resin(A) and 1kg of Hardener(B)

2.MTB-3328 Epoxy Middle (Add Solid Pigments) Coat, 15kgs Kit

- Clear, 2:1, 10kgs of Epoxy Resin(A) and 5kgs of Hardener(B)

3.MTB-3329 Finish Coat, Epoxy Top Coat, 3kgs Kit

- Clear, 2:1, 2kgs of Epoxy Resin(A) and 1kg of Hardener(B)

MTB-3327 Epoxy Primer---Two Components Epoxy Floor Coating System 2:1 Mix Ratio.

Waterproof Barrier, Against Moisture, Corrosion Inhibiting, Excellent Adhesion Designed for commercial, industrial, and residential concrete, cement, wood and tile Floor coating, to penetrate deeper into the pores in order to achieve a better mechanical bond and produce a thinner epoxy film or tie coat that the much thicker base coat can chemically fuse with.

In the middle, install the 3D Effect Stickers.

MTB-3328 Epoxy Middle Coat---Two Components Epoxy Floor Coating System 2:1 Mix Ratio

Waterproof Barrier, Against Moisture, Impact Resistance, Scratch Resistance Designed for commercial, industrial, and residential concrete, cement, wood and tile floor coating, can be used with metallic Color Pigments, Solid Color Pigments Color Flakes, Quartz,Color Granules, Mica Flakes, Polymer Color Flakes, Paint Chips, and Color Glitters.

MTB-3329 Epoxy Top Coat / High Gloss Epoxy Top Coat---Two Components Epoxy Floor Coating System 2:1 Mix Ratio

Waterproof Barrier, Against Moisture, Impact Resistance, Scratch Resistance, Anti-slip and UV Stable Designed for commercial, industrial, and residential concrete ,cement ,wood and tile Floor coating, can apply directly over Epoxy Middle Coating to have a high gloss protective finish.

Heat Resistance 3D Epoxy Floor For Kitchen

Coverage Date

Thickness(mm) | Quantity/㎡ | Package | |

MTB-3327 Epoxy Primer | 1mm | 0.15kgs | 2kgs A+1kgs B |

MTB-3328 Epoxy Middle Coat | 2mm | 0.75kgs | 10kgs A+5kgs B |

MTB-3329 Epoxy Top Coat | 1mm | 0.15kgs | 2kgs A+1kgs B |

Heat Resistance 3D Epoxy Floor For Kitchen

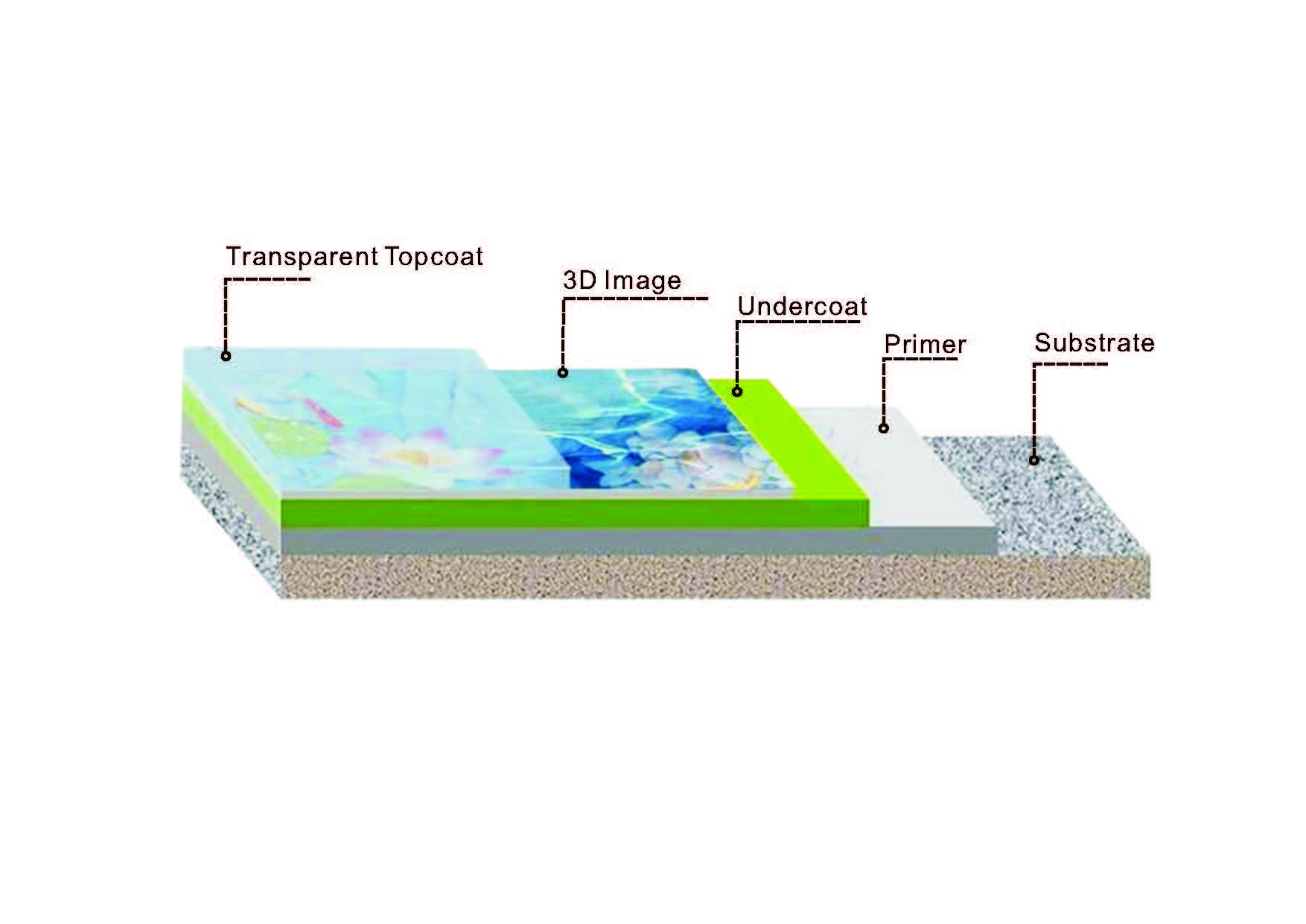

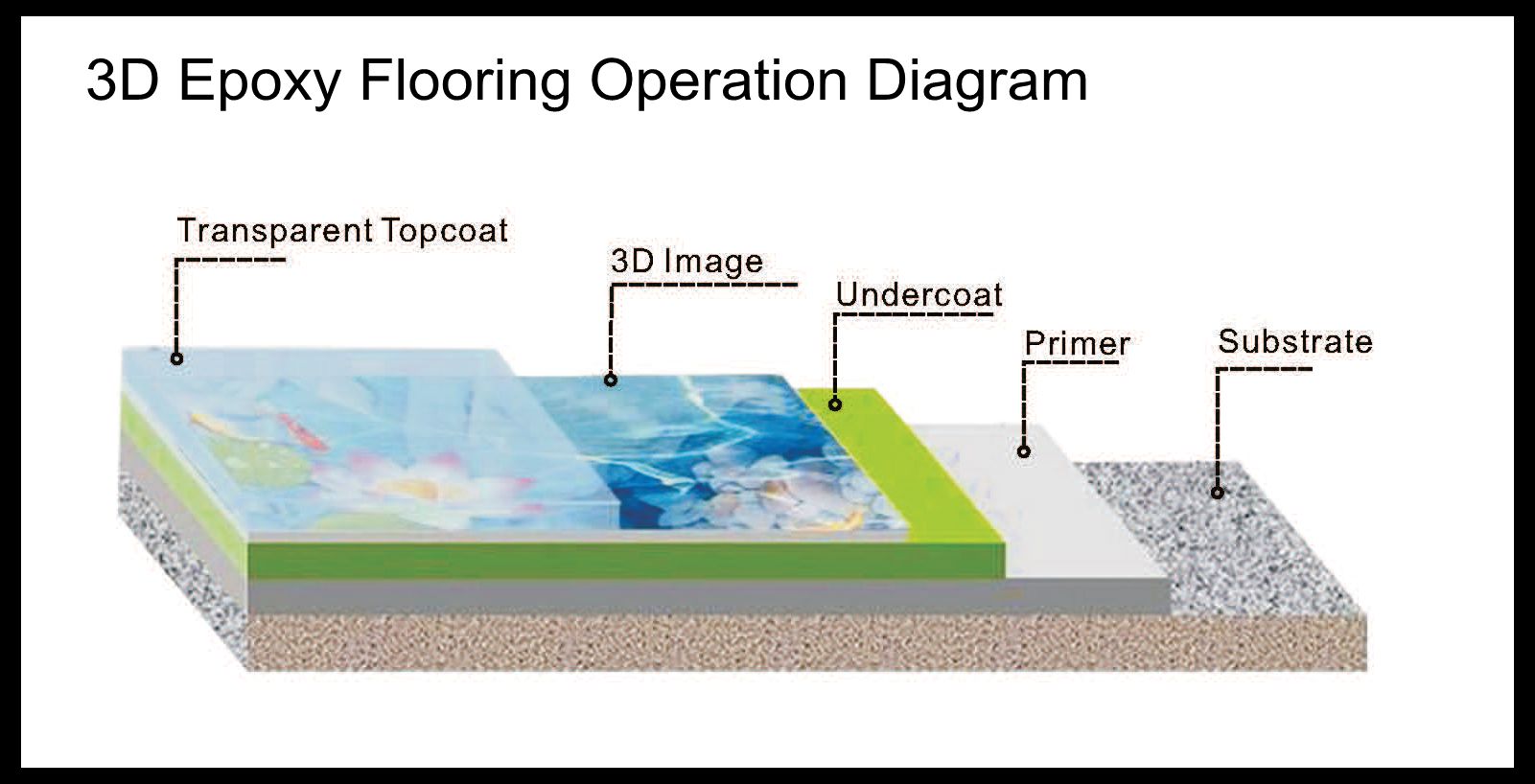

The whole process, you will need: MTB-3327 Epoxy primer+MTB-3328 Epoxy middle coat( mix with metallic colors )+ MTB-3329 Epoxy Top Coat, The using process, pls refer to below diagram and the tips.

How to apply Epoxy on your floor ?

Step by Step Guide to installing your bespoke Epoxy floor

Step 1. Prepare the surface.

Preparation of the substrate is necessary in order to ensure adhesion between the epoxy product and the substrate.

Suitable methods are sanding or diamond-grinding. Any surfaces that have been contaminated with oils may also

require chemical cleaning.

Step 2. Sweeping and cleaning of the floor.

Use an industrial vacuum that picks up even small dust particles. The floor must be cleaned of all dusts and residues

before starting to prime. Otherwise you will have various particles trapped within the coat and adhesion will be significantly

weakened. The less micro-dust on the surface the less primer you will need.

Step 3. Prime the floor with a suitable epoxy primer of MTB-3327

Always prime the floor, don't believe claims that priming is not necessary. Priming will give your floor a longer life and better

adhesion to the substrate. Priming will seal the substrate thus eliminating the risks of bubbles and gasses. Priming helps reduce

the amount of product that will be required in the later stages. Ensure that the areas are ventilated properly. It is common to

coat two layers of primer in order to properly seal the floor. Use a proper electrical mixer to mix the A and B component of the

primer

Step 4. Fill all cracks, holes etc with epoxy grout.

(This step can also take place before priming if you prefer) For thin cracks it may be necessary to slice them with a diamond cutter

before filling in order to improve the anchoring of the grout

Step 5. Install the 3D Effect Stickers.(We can also supply you the 3D stickers and print as your own design,accept OEM&ODM)

Put the 3D Effect Stickers on the surface of MTB-3327 Epoxy primer ,get some MTB-3327 to apply on the 3D effect stickers to

make sure the 3D stickers bond tightly to the cement or concrete floor.

Step 6. Mixing of MTB-3329 Epoxy Resin.

Mix the hardener (part B) with epoxy resin and mix for 3 minutes. Follow this by then mixing the hardener with the Epoxy component (part A)

.Use an electrical mixer and mix at least for 3 minutes. Don't skimp on the mixing! This step is very important. Poor mixing will lead to a tacky

floor! Leave to settle for a few minutes allow bubbles to disperse

Step 7. Apply the product.

Once mixed pour the product in a random pattern across the area you wish to apply your Designer Epoxy foor Resin. Using a notched squeegee

spread the product gently around until you have an even coat on the floors surface. Then use a good quality roller, as poor quality rollers may start

to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Notes:There are a variety of ways to create different finishes, please ask a member of our team or visit one of our approved training centers for training.

3D Effect Stickers what we have at present for your reference .

Heat Resistance 3D Epoxy Floor For Kitchen

- Shopping Malls

- Automobile

- Showrooms

- Hotel & Casinos

- Auto Dealerships

- Animal Hospitals

- Atriums

- Banquet Halls

- Bars, Clubs & Pubs

- Bathrooms

- Cafeterias

- Churches

- Clean Room

- Commercial Kitchens

- Dairies Food Processing

Plants

- Firehouses

- Greenhouses

- Grocery Stores

- Hallways/ Corridors

- Kennels

- Laboratories

- Laundromats/Dry cleaners

- Locker Rooms

- Art Galleries & Museums

- Offices

- Pet Stores

- Restaurants

- Restrooms

- Retirements Homes

- Salons/Spas

- Stadiums

- Veterinary Clinics

- Wineries

- Collegiate & Professional Sports complexes

Heat Resistance 3D Epoxy Floor For Kitchen

- Easy of Maintenance

- Aesthetic Improvements

- Hard and Abrasion Resistant

- VOC Free, 100% Solid, No Odor

- Stain and Chemical Resistant

- Anti-microbial & Anti-slip

- High Loss Finish Like Mirror

- Special Colors can match design or preferred colors

- MTB-3327 Epoxy Primer, 3kgs

- MTB-3328 Epoxy Middle Coat, 15kgs

- MTB-3329 Epoxy Top Coat, 3kgs

Shipping

It will be better if your have your own forwarder to take care of the shipping.

If not, our professional forwarder can help you. DHL/FedEx/UPS/TNT/EMS/By sea and so on are optional. We can send goods by shipping ways you want.

For samll order, we suggest express, shipping time is about 5-7 days.

For larde rorder, we suggest cheaper ocean shipping. It will takes about 20-30 days.